If boxing is the ultimate blue collar sport, factory work is the quintessential working class vocation of today.

During Stephen Mitchell’s career as a maintenance and facilities manager, he was often left feeling slugged – and is now fighting back with his tech startup SQCDP.co.uk.

Mitchell – known across the North East factories and tech scene as Mitch – was working at a large defence manufacturer when COVID brought the inefficiencies of paper-based systems into sharp focus.

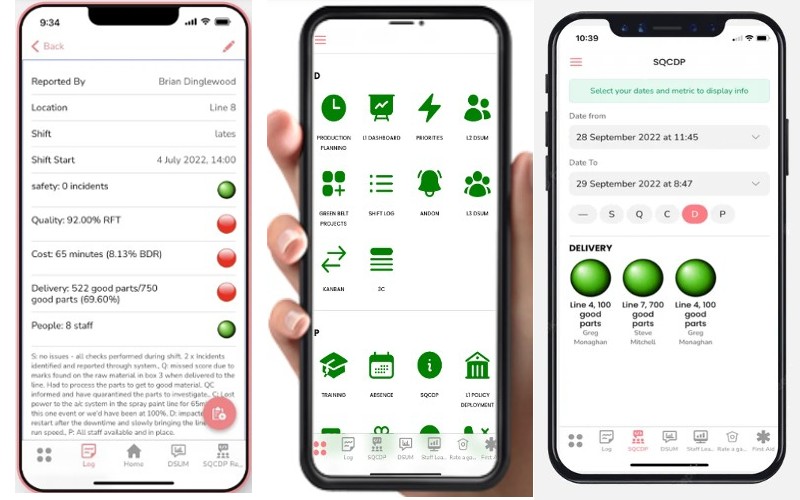

“The process is known as SQCDP and comes from lean manufacturing in the 60s and 70s, where they boiled things down to the lowest common denominator,” he explains to BusinessCloud.

“S is for safety, a measure of accidents, incidents, near misses, observations; Q for quality of the products; C for cost control; D for delivery of products against a target; and P for people – are we using the right number of people in the process?

“It works as a system, but when deployed manually through paper and whiteboards, it fails the business because there’s so much processing in there.”

Gemba walks

The pandemic saw the traditional manufacturing plant ‘gemba walks’ – a Japanese-monikered workplace walkthrough for observing and consulting employees on the frontline to identify productivity gains – replaced by morning meetings in a central open space.

The 15 whiteboards, each containing 150 data points alongside ‘headlines’ in red or green – highlighting whether they required action to fix an issue – were moved from alongside the workcells to this hub.

“The sheer volume of it was so noisy! If I was seeing one thing that was important, the others in the room might have been looking at a different issue highlighted in red – which meant that we weren’t aligned,” says Mitch.

“And the boards weren’t being fully updated: for example, on the D for delivery, there would be a red mark and nothing beyond that. The person hosting at a meeting might say: ‘We think there was downtime on the machine’… then I, as maintenance manager, would look to resolve it.

“But it would turn out to not be a machine problem at all – the problem was that the raw materials hadn’t arrived on time or something. This knowledge and data was somehow not being captured in that manual system.”

Feeling the heat

The inefficiencies, Mitch says, invariably led to what is known as ‘recovery’. “The business was taking a hit for overtime again and again – either a Saturday morning or a full Saturday – because they had to meet the deadline [to deliver for the client] by the end of the weekend.”

He adds: “From a personal perspective, I was also feeling the heat: I felt people were looking at me all the time and I was having to defend myself.

“I felt like I was in the boxing ring! I was in the corner, having to find the answers, when the problem all along was the system.”

Determined to find a solution, none seemed to exist – and so he took matters into his own hands.

“I started to go to Costa Coffee at 6am on my way down the A1 to work every day,” he says. “I’d be the first one there when the doors opened and get an hour in, working on the SQCDP platform with a low-code builder.”

Despite never having coded before, he intrinsically understood the problem: “I’d had to be good with Excel spreadsheets and working in a logical way, so I knew I’d find my way through until I had something to show the production managers.”

MVP

The app and software platform, an alternative to hardware-derived, expensive smart factory solutions, connects teams rather than machines. A two-week trial of the minimum viable product yielded a 15% gain in productivity and 5% improvement in ‘right first time’ quality.

Mitch says he knew they were on to something, but the business ultimately couldn’t deploy the system through its backend, which he found “soul-destroying”.

He moved to another manufacturer in Cramlington and within a fortnight realised the company was plagued by these same issues. “It was at that point that I was like: ‘Is there a product in this? Is there a business in it?’ So I started to explore.”

At a social event held by North East accelerator Ignite, he met Nikhil Patel, the CTO of Grid Finder – since acquired in a seven-figure deal – who is now an angel investor in the business. “I was explaining that I’ve got two kids and how difficult it would be to jack in the day job, but Nikhil just cut through. He was like: ‘Just f****** do it!’”

Igniting the fire

Mitch decided to “burn the bridges” and quit his day job after securing a place on the Ignite pre-accelerator: £10,000 of grant funding, alongside financial help from his family, got him through the first six months.

A familiar face then came on board as technical founder in Brian Russell, a solutions architect with three decades of IT experience including 15 spent architecting government projects and working with global blue-chips.

“We went to school together!” Russell reveals. “We’ve known each other since we were 12: we played for the same football team, knocked about together… but we just lost contact.

“Then Mitch contacted us out of the blue [following a flurry of LinkedIn recommendations] and we’ve picked up where we left off.”

Russell is very complimentary of Mitch’s coding efforts: “What he’s built on MVP has been absolutely fantastic. For someone who hasn’t been in that line of work, he obviously understands the product.

“From my point of view, it’s just basically building it into an enterprise solution now, improving the code, it’s building the front end; building the APIs; then building a segregated database. Cybersecurity is essential if we’re going into these global companies.

“But the IP that Mitch has got – his understanding of the problem and solution – is the magic dust.”

Pre-seed funding

SQCDP has now validated its early platform through four customer trials and already onboarded manufacturers to pay for the product. Its biggest win is a major automotive manufacturer which is agreeing to pay for its annual licence in advance to help with cash flow.

The startup featured on our sister site TechBlast’s North East & Tees Valley Startups 2.0 list late last year and Mitch won our Pitching Night competition – sponsored by Ignite – ahead of 13 other entrants. With an apprentice developer coming on board, he is also halfway towards securing a £500,000 round of pre-seed funding.

Mitch has put time in on the factory floor with his SQCDP platform and is clearly passionate about solving the problem for all parties.

One team

“It’s a traditional blue collar frontline-type environment and these guys on the floor are frustrated – they just want to run! They are there to produce and then go home. They want those daily challenges out of the way.

“We aim to make it physically and mentally easier for them to do that: our platform is their opportunity to tell the story of what has gone wrong and the things they need support on, as well as the areas for them to work on and improve.

“It’s also giving them a sense of purpose: if they have the right tools, they’ll do a really good job for you. But if they’re neglected and ignored, and beaten up every day, they won’t care – they can’t care!”

Improving performance day by day is also crucial to securing their future, explains Mitch. “In manufacturing, you’re close to the product, you’re close to the customer – and you’ve got to do it within those margins otherwise profitability disappears.

“The culture created with SQCDP is to find out what’s threatening performance and then resolve it. That’s the whole plan: get better by understanding the real data.

“A plant will have an average overall equipment effectiveness score. If one has a score of 32% and another, which could be overseas, is 72%, where do you think the parent company would put the money?

“Each plant manager is striving for that headline metric to go: ‘We’re running an efficient ship, and we’re continuing to improve.’ And that then gets cascaded right down the chain to the guys who tend to have the least information and don’t get things by email… by actually allowing them to see the impact of their performance.

“That empowering culture is the holy grail of management: it means we’ve all got one story.”

Harking back to their days in youth football, Russell reveals he was the Alan Shearer of the team – but full-back Mitch was akin to modern-day Newcastle United star Kieran Trippier.

“When we’ve built up the business into a global powerhouse, we’re getting a box at St James’!” he jokes.