A country pub in Wales is the last place you’d expect a tech unicorn idea to hatch – but that is exactly what Sam Burgess is looking to execute.

The proud Mancunian and Army veteran founded SamsonVT – 15th on our recent FactoryTech 50 ranking – with Ed Brunyee, then a corporate finance adviser specialising in cloud technology, following the chat over a beer.

“I’d known Ed for many years. He was working with immersive technologies at Deloitte at the time,” CEO Burgess tells BusinessCloud. “We were in a pub in the middle of Wales and he showed me this stuff. I said ‘if we could repurpose that for after sales…’

“That was the lightbulb moment. From that point on, we set about trying to build a business to do just that.”

Burgess – not to be confused with his namesake, the England dual-code rugby legend – honed his skills around engineering support systems while travelling the world as a team leader with the Royal Engineers then working with non-governmental organisation Mines Advisory Group in former conflict zones.

“It’s one thing designing a support system, and another living in Africa and implementing a support system! Something like that definitely sharpens the pencil a lot more than the theory side,” says Burgess.

As an engineering consultant advising global manufacturers on after sales strategies – a market worth an estimated $400 billion – he fully understood the challenges these OEMs face when managing the lifecycle of equipment.

Seal of disapproval

“I’ll give you a personal example, but it scales to any level,” he says. “I have a power washer from a well-known brand, and one of the seals broke so I needed to order a new one: I visited the website and simply couldn’t find the part I needed for that particular model. In the end, I went on to Amazon and bought a Chinese knockoff instead.

“So what happened there is my view of the manufacturer decreased significantly because they couldn’t even show me the part number; I then had to go and buy a third-party product so the manufacturer lost out on parts revenue.

“It’s a lose-lose situation – and it’s the status quo, where OEMs rely on a total static PDF paper-based platform for after sales.”

Founded in 2017 and initially bootstrapped alongside his consultancy work, SamsonVT fully digitises this process using 3D models and technical information already available within OEM design documents.

It has two elements – aftermarket sales platform Partful and 3D work instructions platform Workflo – which Burgess says are intrinsically linked. “When you need a new part, you order it; then when it turns up, you need to replace it,” he says.

“We split them up from a market perspective because there are two different stakeholders: from the C suite and senior level you’re very interested in both aspects, but the actual people who feel the pain are your parts managers and your training managers: they are different human beings and they have different drives.”

https://businesscloud.co.uk/company/samsonvt/

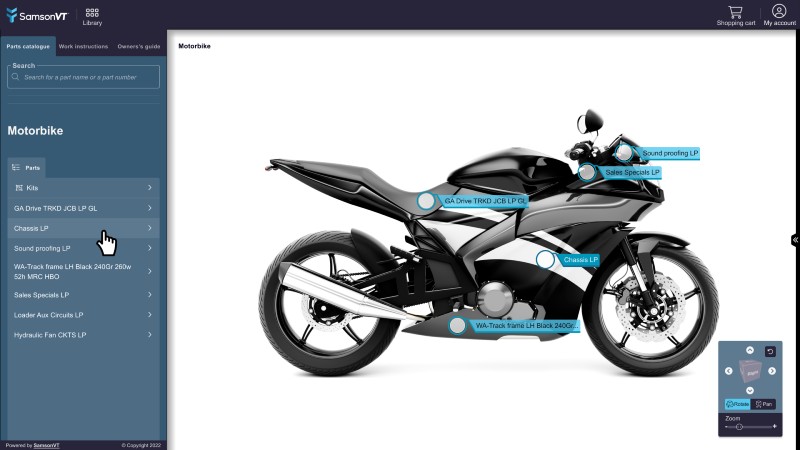

Partful

Partful is a digital product catalogue that enables customers to quickly identify replacement parts using 3D visualisations – and then place orders instantly with manufacturers.

“You can now put the information that your user needs, whether that’s a dealer or customer, in their hands via a mobile phone at the moment they need it,” adds Burgess. “It doesn’t matter if you need a drive belt for your lawnmower or for your Lotus.

“Our platform ingests [the OEM design information] and spits out a 3D model optimised to work on a web browser: you’re giving people access to that information anywhere in the world with an internet connection and a relatively good mobile phone.”

Workflo

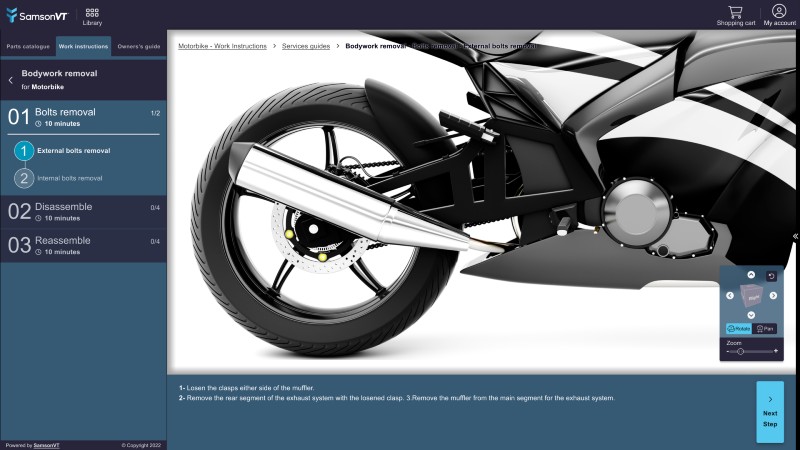

Workflo is an interactive 3D work instructions platform that delivers accurate product knowledge and training to multilingual teams on a global scale.

Again offering a personal example, Burgess – a self-confessed ‘petrolhead’ and mountain biker – explains: “If I need to repair one of my bikes, I’ll watch a YouTube video rather than take an expensive training course or paying over the odds for a mechanic to look at it. But Dave up in Grimsby’s instructions for fixing the product might not align with the OEM’s view of the world!

“We can create work instructions as directed by the OEM and, because we’re connected in the cloud, any changes are instantly populated to everybody around the world. So whenever anybody opens up that Workflo work instruction, they know the information is accurate right at that moment in time.”

Angel & crowdfunding investment

As he looks to build SamsonVT from Manchester, the CEO has long left behind his consultancy work. Customer traction increased with continued funding from an unnamed angel; then, just before COVID hit in 2020, a £400,000 round of crowdfunding on Seedrs and Innovate UK grant gave it further firepower.

“We got lucky with our angel investor: through mutual friends, he knew us as people and our outside capabilities as individuals. So I think that probably made up for a lot of the lack of understanding [about the need for our solution] within the industry.”

He adds: “Selling the messaging on Seedrs was probably one of the biggest challenges we had to get right: I come from this world and I can see the problem we’re solving really well, but in the world of crowdfunding, it’s not quite as obvious.

“This is also common within the industry: if you look at where all the money is spent within immersive technologies, the vast majority is still in the design phase. The biggest value is in the support element, but it’s forgotten.

“Everybody who works in after sales knows intrinsically that all the focus gets put on the design and then, when it comes to supporting that asset or fleet or whatever for the next 10, 20, 30, maybe even 40 years, people just switch off because it gets really difficult.

“But if you get it right, it can – by a significant amount – be a far greater and more profitable section of the business.”

Seed funding & Series A

SamsonVT now has 20+ customers across several industries – including global businesses Lotus, RS Components and Norton Motorcycles – having raised $5.1m in seed funding at the start of this year. Headcount recently reached 40 – up from 15 last year – while the startup has opened a European Centre of Technology in Poland.

The investment was led by Par Equity, with participation from US-based Blumberg Capital. Advisors at Sand Hill East are supporting the firm through its next phase of growth in sales, marketing and business development, as well as strategically preparing for entry into the US.

“We’re in negotiations with some of the biggest plant manufacturers in the world at the moment, which is really exciting,” says Burgess. “We’re on track to reach £1.5m annual recurring revenue in the next 12 months, which will line us up for a Series A [round of funding] in summer 2023.

“If we get the next 12 months and the Series A right, we’re pretty confident that we’ll be the next Manchester unicorn.”

https://businesscloud.co.uk/factorytech-50-uks-most-innovative-manufacturing-technology-creators-for-2022/